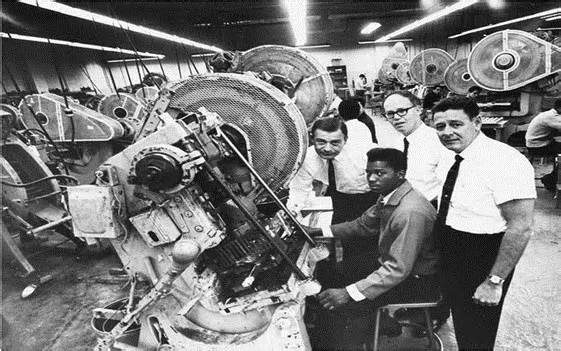

Brian continued, “Our beginnings were really modest, but also auspicious and magical. We started in 1954 with five workers in a small garage in Woodside, Queens, in the shadow of the 59th Street Bridge. Our sales in 1954 were $124,206. 58 and our pre-tax profit was $877. 38 (you see, we’ve had a “trick” to make money). We paid $226. 21 in taxes that year. At first, my mother, the daughter of a World War I hero who fought in The Trenches, would come to do the bookkeeping in a closet at the back of the establishment. He hand-wrote Park. Era’s first invoice for GE Schenectady for $300.

Brian added, “Jerry and Tony’s purpose in creating Park was to create something different and special. . . to achieve something great. . . achieve greatness. It’s his legacy. They weren’t interested in mediocrity.

Brian concluded, “Jerry and Tony sacrificed so much for us, overcame so many obstacles, and persisted through so many dark days when things seemed hopeless for us. We will be deeply grateful to Jerry and Tony for all they have done for us and for leaving us a legacy of unwavering and uncompromising determination toward greatness. We owe everything we have and everything we are to our beloved founders, Jerry Shore and Tony Chiesa. Thank you, Jerry and Tony.

Park Aerospace Corp. develops and manufactures complex hot melt composite fabrics and responses that are used to produce composite structures for global aerospace markets. Park’s complex composite fabrics come with adhesive films (Aeroadhere®) and lightning protection fabrics (Electroglide®). Park offers a variety of composite fabrics, specially designed for manual placement or automated fiber placement (AFP) production applications. Park’s complex composite fabrics are used to produce number one and secondary structures for jet engines, giant and regional transport aircraft, military aircraft, unmanned aerial vehicles (UAVs, commonly known as “drones”), business jets, aircraft general aviation and rotary wing aircraft. . Park also offers specialized ablative fabrics for rocket engines and nozzles, as well as fabrics specially designed for radome applications. Complementing Park’s complex composite fabric offering, Park designs and manufactures composite portions, structures and assemblies, as well as low-volume tooling for the aerospace industry. Target markets for Park’s composite portions and structures (which come with Park’s proprietary SigmaStrut™ and AlphaStrut™ composite product lines) include, but are not limited to, prototype and progression aircraft, special project aircraft, aircraft replacement parts civilian and ex-military and exotic spaceships. . Park’s purpose is to do what others possibly would not or cannot do. When no one else needs to do it because it’s too hard, too small, or too boring, sign us up.

You can get a photo to accompany this ad on https://www. globenewswire. com/NewsRoom/AttachmentNg/02e29ca3-1cbe-47ee-b1ec-d072a2f75fbb