A device designed to collect microparticles from car tires as they are thrown has earned the team that created it a James Dyson Award. An organization of masters scholars from Imperial College London and the Royal College of Art calling themselves the Tire Collective have received the UK Foreign Festival Award for their solution that can reduce the devastating pollutants caused by tire wear.

Modern tires are made from man-made rubber, wire, plastic-based cloth, and other fabrics, and almost everyone at some point has had to upgrade a worn tire as they disintegrate from friction with the road.

In Europe alone, this produces 500,000 tonnes of airborne tire waste consistent with the year. A 2017 by the International Union for Conservation of Nature estimated that tires account for up to 28% of all microparticle waste in the world’s oceans.

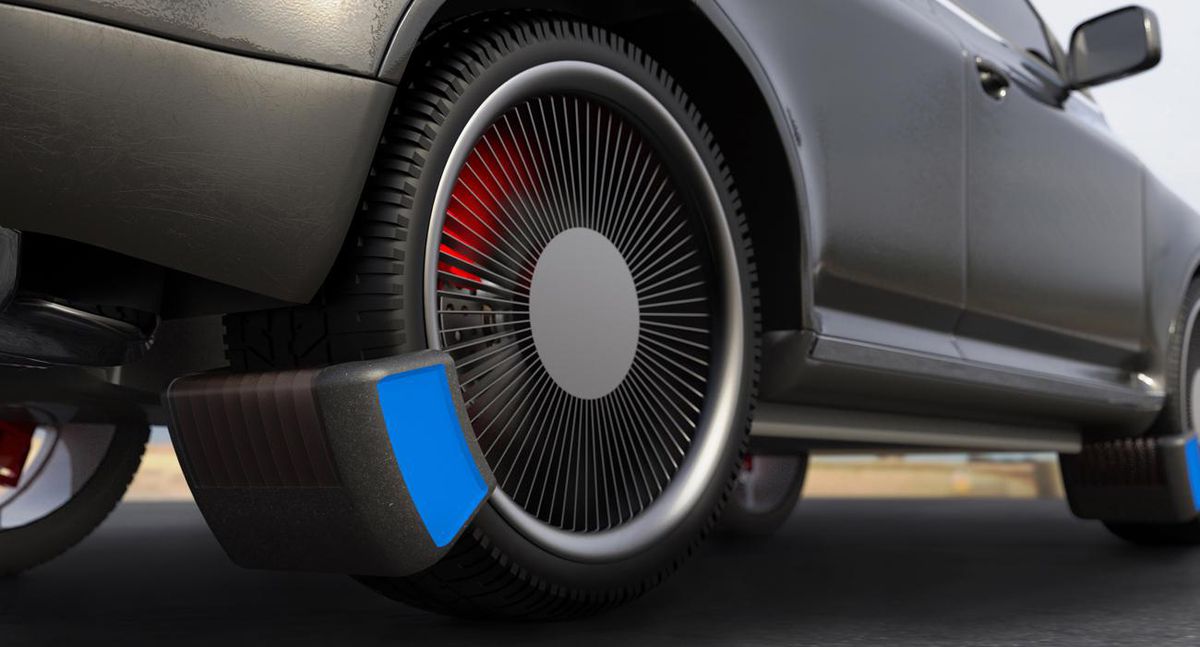

The device is attached to the axle stub and is free to move and rotate with the suspension. This makes it adaptable to other vehicles. It is located near the junction of the tire with the road, with enough free floor space and takes advantage of the air around the spinning wheel.

The team found that the rubber debris from the tire was definitely loaded due to friction. Using a series of single electrostatic plates on a verification bench, the prototype design captured 60% of all airborne debris. Captured tire debris is stored in an internal cartridge of the device and collected for maintenance. It has low power consumption and can be powered directly from the car’s alternator.

Hugo Richardson, M Deepak Mallya, Hanson Cheng and Siobhan Anderson, graduates of the Innovation Design Engineering Master’s / Master’s program jointly administered by the two schools, said that they have a percentage of obstacles to the environment and use design to have a significant effect on society.

“As a team, our strength lies in our diversity,” said Hugo Richardson. “We come from all over the world and bring a wealth of knowledge in mechanical engineering, product design, architecture and biomechanics.

“It is not unusual wisdom for [sic] tires to wear out, yet it turns out that no one thinks about where they are going, and we were surprised to find that [sic] tire waste is the biggest microplastic contaminant in our products. oceans. At Tire Collective, we incorporate sustainable circular values into product design to capture tire wear at its source. “

Once captured, the fragments can be recycled and reused in new tires or other materials. The device can also provide real-time knowledge of the wear rate in relation to driving behavior and environmental conditions. The organization published business card inks made from collected tire dust, while other prospective programs include 3-d printing, soundproofing, or even the production of new tires.

A study published in Nature Communications reports that the Atlantic Ocean comprises between 12 and 21 million tons of microparticles, or microplastics, debris, much more than we thought in the past and that they come from various sources. For example, each and every time you wash clothes in a washing device, tiny fibers are released and most of the time they end up in the oceans.

According to recent research on the effect of washing clothes, millions of tons of microplastics have been released from clothes into the environment for more than 70 years. An estimated 5. 6 million tonnes of tiny debris were released into aquatic and terrestrial environments between 1950 and 2016, some of which was released in the last 10 years alone.

Car tires are the largest microparticle pollutant in the oceans after single-use plastic. Research recently carried out through the Norwegian Institute for Aviation Research found that more than 200,000 tonnes of small plastic debris are dumped from roads into the oceans annually.

Unfortunately, the challenge will only get worse, at least in the short term, as electric cars tend to be heavier than their fossil fuel equivalents, which means more tire wear.

Following its victory in the British segment of the James Dyson Award, the design will enter the foreign competition. Contestants are narrowed down to a short list of just 20, to be announced on October 17, and then the foreign winning submission will be announced on November 19. They will win £ 30,000 ($ 38,800) in prizes in addition to the £ 2,000 ($ 2,587) awarded to national winners.

Founded through British inventor James Dyson, famous for being the pioneer of the bagless vacuum cleaner, the award is in its 16th year and operates in 27 countries. It is open to undergraduate scholars and recent graduates in engineering, business design, and product design. Recognize and reward cutting-edge design responses to global upheavals with the environment in mind.

Scott has written about science and generation for 20 years for publications around the world. Covers environmental generation for Forbes.